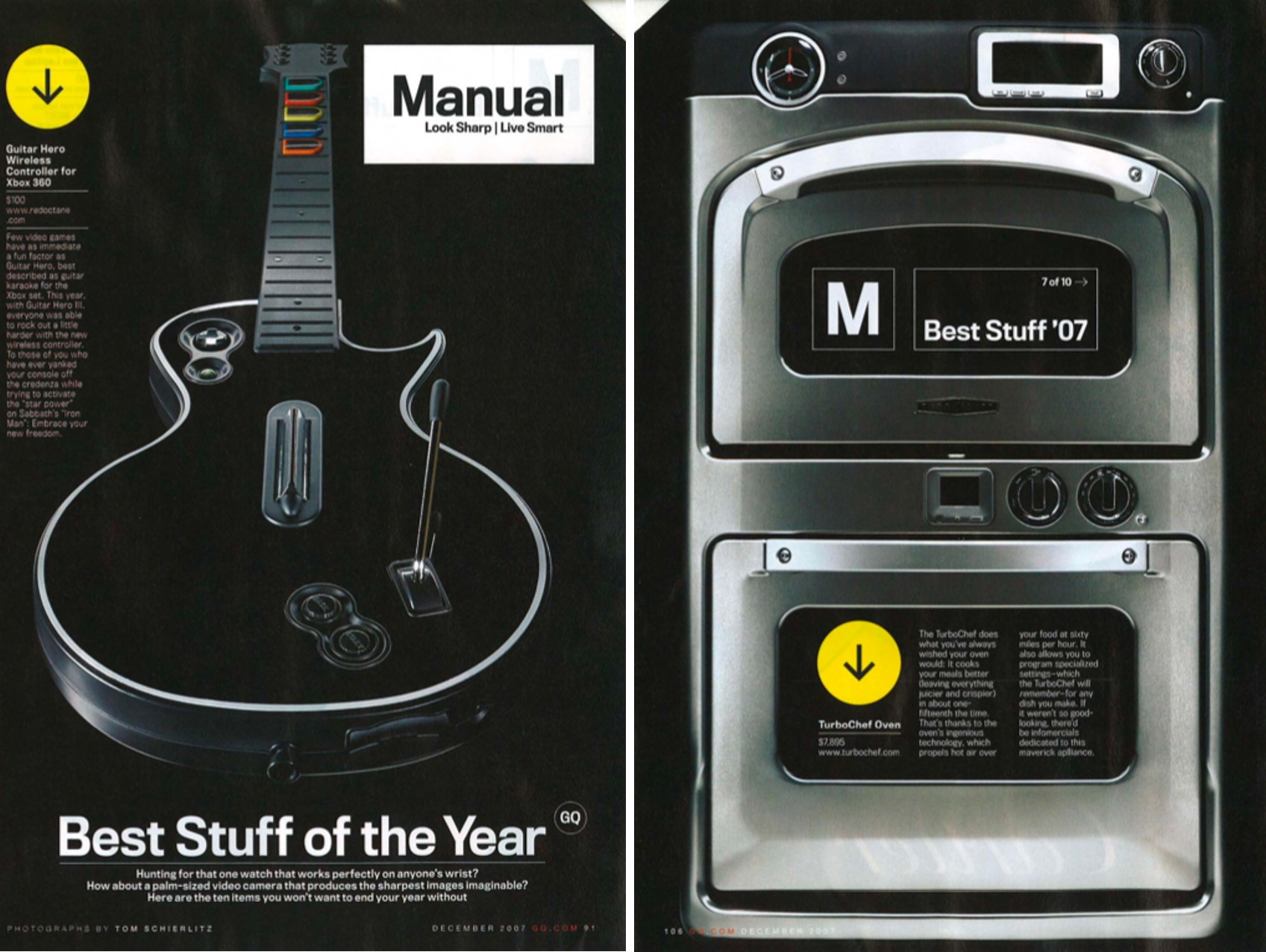

Turbochef Double Wall Oven - I was the engineering lead on this project in 2005 working closely with the industrial designer and the interaction designers to deliver a cohesive user experience including the industrial Deisgn and user interface. I sourced the unique aspect ratio display and the switch technology in the CookWheel which is the primary input method in the user interface. I also built the complex external part files in Pro Engineer which was my first project using the software. To prove out the UI, we built a full scale working appearance model of the oven with UI prototype using a Mac Mini, Belkin Powermate knob, and in-car display system. I worked with the Turbochef team to design the unique hearth-shaped door with rectangular choke to meet microwave safety requirements and resculpted the door before pilot production to allow a stainless steel version to be produced with a progressive die stamping. The project also had me doing detailed mechanical design of upper and lower display assemblies and found suppliers for electronics components like a stepper motor driven clock which could function even during the 225° self-clean mode. I was named in several patents for this project.